E-mail:

sales@cangao.cn

+86 311 8225 1293

The Kiln Drying Machine makes the moisture in the wood evaporate and dissipates, so that the moisture content of the wood is reduced, and the wood is prevented from being mildewed or eroded by insects and wood splitting and deformation during storage, transportation and use.

The Kiln Drying Machine makes the moisture in the wood evaporate and dissipates, so that the moisture content of the wood is reduced, and the wood is prevented from being mildewed or eroded by insects and wood splitting and deformation during storage, transportation and use.

It is suitable for efficiency eliminating the stress of timber (especially secondary drying and balancing of timber), quick drying of large cross section thick timber, quick drying of hard timber ( especial redwood ), quick drying of small batches of timber, drying of floor and surface plate, drying of single plates, etc.

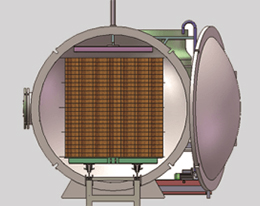

Adopts High frequency drying technology, inside and outside of wood timber is heated at the same time, uniform heating, high speed drying, short drying time and good quality. Which can keep the timber nature color, meanwhile, the timber is aerated under the vacuum environment, non-cracking,especially applied for the thick and hard wood, or secondary drying for wood.

The timber is vaporized at low temperature in vacuum environment and is not easily deformed and cracked.

It can also dry blank for solid wood flooring, the veneer flatness is good and operation is simple.

Timber stress can be effictively eliminated and timber moisture content can be balanced.

It is eco-friendly and safe and does not require a boiler.

Typical drying parameters: The dry thickness of hard timber ( red timber ) is 6cm, it only takes 6 days to dry rosewood with moisture of 35%-50% to 11%-13% and secondary balanced drying of timber can be performed ( only taking several hours ).

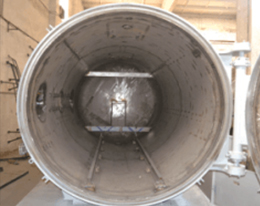

The overall tank body is made of 304 stainless steel, all pipelines are made of 304 stainless steel, resistant to rust to protect klin body and pipelines from regular anticorrosion maintenance and pollution of timber.

| Type | CGGZ-3 | CGGZ-4.5 | CGGZ-6 | CGGZ-8 | CGGZ-10 | CGGZ-12 | CGGZ-14 | CGGZ-20 |

| The effective packing material size (m)(H)×(W)×(H) | 1×1×3 | 1×1×4.5 | 1×1×6 | 1×1×8 | 1×1×10 | 1×1×12 | 1×1×14 | 1×1×20 |

| Effective volume (m³) | 3 | 4.5 | 6 | 8 | 10 | 12 | 14 | 20 |

| HF power (kW) | 30 | 30 | 60 | 80 | 80 | 80 | 80 | 100 |

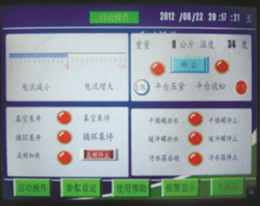

| Human-machine interface | Touch scteen operation Automatic | |||||||

| Vacuum degree (Mpa) | -0.07~-0.09 | |||||||

|  |  |

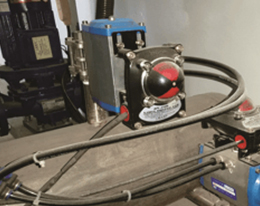

▶The overall klin body is made of 304 stainless steel. | ▶Stainless steel material for manhole ellipsoidal head and glange. | ▶Stainless steel vacuum pump and electromagnetic valve. |

|  |  |

▶304 stainless steel cooling tower. | ▶PLC automatic control, touch screen and human-machine interface, worker only needs to set the basic parameters, such as drying technology, intial moisture and requested finial moisture, automatically control whole drying process. | ▶Weighting measurement method accurate wood moisture content. |

|  |  |

▶The machine equips a hydraulic platform at the top of drying klin, so the timber is dried under pressure without deformation. | ▶The kiln bodyis equipped with rock wool to provide thermal insulation so that the temperature in the kiln is even and electricity. | ▶Using double temperature measurement system-optical fiber an thermocouple. |

Customers Scene

The furniture factory in Mexico adopts our HF timber dryer machine, which can save drying time(save two-thirds) and improve the drying quality.

Copyright © Shijiazhuang Cangao High Frequency Machinery Co., Ltd. All Rights Reserved | Sitemap |