E-mail:

trade@cangao.cn

+86 311 8225 1293

Many parts of solid wood furniture are very large, in the actual production of such a large piece of wood cost is very high, but also impractical, so in most cases, we see the solid wood furniture is made of splinters.

The solid wood panelling process can effectively increase the area of the panel, but also to improve the wood material, save natural resources, expand the use of wood and the most direct way to design areas. HF joining machine for wooden board supplier will explain what factors affect the solid wood panelling process.

Most enterprises and users are more concerned about the appearance of solid wood splicing board, and the surface warping deformation, cracking of the glue layer, finger tenon off fracture and other quality problems lack inspection standards and management methods, often using simple repair to cover up, to a certain extent affect the development of the solid wood splicing board industry.

Due to the internal stress of wood, in some special circumstances will occur cracking deformation. In the process of solid wood splicing board, internal stress and will be affected by the density of wood, moisture content, surface roughness, splicing method, glue species, glue amount, gluing pressure and the temperature and humidity in the air.

Gluing is a necessary part of the splicing process, when the type of glue used does not match the wood, it will lead to the low strength of the splicing glue when the splicing is not firm, easy to crack. In addition, a reasonable grasp of the amount of glue coating is also directly related to the selling process.

When the amount of glue application is too low, the board will have a lack of glue and uneven distribution of adhesive, etc. When the amount of glue is too high, the glue layer is too thick, the volume contraction of the glue layer when curing will produce internal stress and will destroy the cohesion of the adhesive, reducing the overall adhesive strength.

Gluing pressure is also an important influencing factor, pressure is conducive to the full penetration of the glue so that the glue and wood active molecules combined to form a uniform glue film. But the unsuitable pressure is easy to make the glue extrusion, produce a lack of glue, glue phenomenon, while the larger pressure will make the material deformation serious and the formation of greater stress.

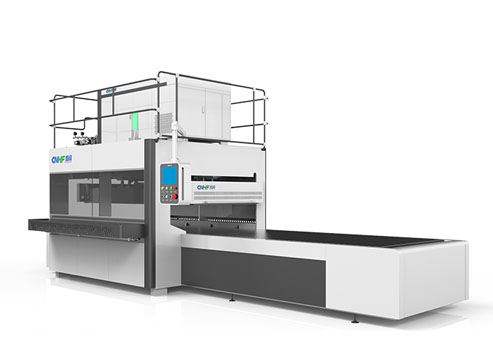

Shijiazhuang Cangao High-Frequency Machinery Co., Ltd. is a manufacturer specialized in design and product high-frequency heating equipment, hydraumatic and pneumatic equipment, as well as non-standard equipment for metallurgy and food industries. The products are widely used in furniture, man-made boards, floor panels, packing, instrument, hand- crafts, plastics, textile, food, and chemical fields.

As the "New and High-tech Enterprise of Hebei Province", Cangao introduces the quality management system of IOS9001:2008 and its products have passed the CE certification of the European Union. On such basis, Cangao has established a modern management mode and has been cultivating a team of learning talents, so as to provide a powerful guarantee for future development.

If you want to get more information about high-frequency heating equipment price,please contact us.

Previous:

None

Previous:

None

Copyright © Shijiazhuang Cangao High Frequency Machinery Co., Ltd. All Rights Reserved | Sitemap |