E-mail:

trade@cangao.cn

+86 311 8225 1293

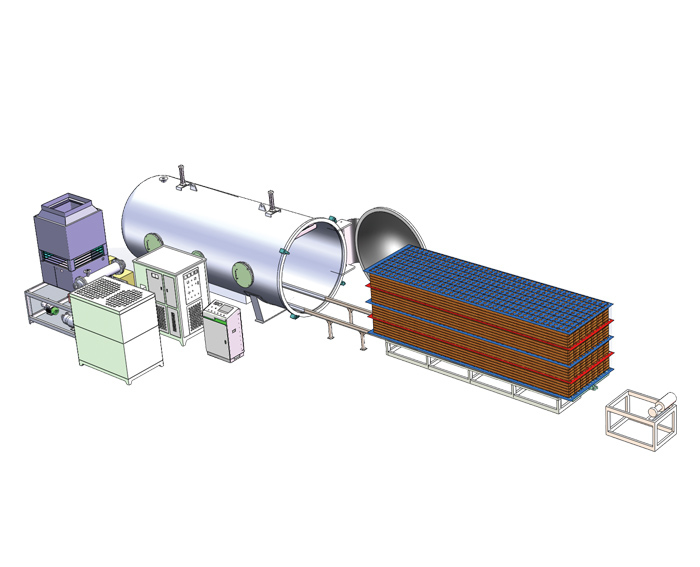

The high-frequency vacuum wood dryer is a new type of wood drying equipment. It adopts high-frequency drying to heat the wood inside and outside at the same time. The heating is uniform, the drying speed is fast, the time is short, and the natural color of the wood can be maintained. At the same time, it has the advantages of low temperature and quick-drying under vacuum conditions. It is suitable for mahogany, hardwood, thick wood, ultra-thin veneer, and large-section square wood. Common precious woods such as rosewood, wenge, huanghuali, etc. At the same time, it is also suitable for the secondary drying of small batches and expedited wood regain.

HF dryer machine is the perfect combination of high-frequency heating and vacuum dehydration.

main feature:

1. It adopts PLC and touch screen program for automatic control, various heating parameters are simple and clear, and the wood drying process can be fully automatically controlled by unattended personnel.

2. Optical fiber is used for temperature detection to avoid high-frequency interference during heating. Accurate measurement and control methods further ensure the drying quality of wood.

3. The top of the dryer is equipped with a hydraulic system, which exerts pressure on the pile of dried wood to further ensure the uniformity of the dried wood and prevent the deformation of the wood.

4. Humidity detection adopts the weighing detection method, PLC controls the moisture content of wood according to the change of wood weight. To avoid the influence of high-frequency electromagnetics on traditional metal probes, it is more accurate and automated.

5. The tank body is anti-corrosive and does not rust.

6. Automatic feeding and discharging are simple, labor-saving, and time-saving.

Common faults and troubleshooting methods of the high-frequency machine:

1. High frequency cannot be added.

The door switch behind the chassis is not closed. Open the door and pull out the button of the door switch.

The "high pressure on" button is not in good contact. Check or replace the button.

The filament of the electronic tube is not bright, check whether the voltage of the filament is normal, if the voltage is normal, remove the connection screw of the filament wire, polish the connection point and then connect it.

Check if there is any disconnection in the internal wiring.

2. There is a fire phenomenon in the high frequency.

Check the location of the ignition and polish it with fine sandpaper.

The anode or grid current is too large, adjust to the appropriate position.

Check if there is any short circuit in the load workpiece.

3. There is a fire on the load.

Check if there is a short circuit on the positive and negative poles of the load. If there is any separation, clean the place where there is fire.

Check whether the positive and negative poles are too close. The reasonable distance between the positive and negative poles should be more than twice the thickness of the workpiece.

See if the edge of the positive electrode is too close to the frame. The edge of the positive electrode should be more than twice the thickness of the workpiece.

Check whether there are impurities in the insulation board, and clean them if there are any.

The above information is provided by high frequency joining machine manufacturer.

Copyright © Shijiazhuang Cangao High Frequency Machinery Co., Ltd. All Rights Reserved | Sitemap |