E-mail:

trade@cangao.cn

+86 311 8225 1293

The dryer machine uses electricity as a heat source and heats the air by convection of the heat exchanger through an axial fan. The hot air layer transfers heat through the wood, fresh air enters the dryer machine from the air inlet to replenish, and is discharged from the moisture outlet, constantly replenishing fresh air, continuously discharging the hot and humid air, maintaining the appropriate relative temperature in the dryer machine, and saving energy. This is the dehumidifying technology of the wood dryer machine. Most of the hot air circulates in the box for dehumidifying and drying.

The power of the electric heat sink radiator in the dryer machine has a certain relationship with space, and the heat dissipation volume can be obtained by calculation. The surface of the electric heat sink tube is made of aluminum (or stainless steel) heat sink to increase the surface area of the radiator Thermal efficiency. Using the adjustment of the fully automatic temperature adjustment system to control the temperature change in the drying oven, reduce the cost of manual control, and improve the drying quality. Reasonably adjust the amount of hot air ventilation, evenly ventilate layer by layer, without all-round hot air supply and dead corners, so that the wood can run evenly and dryly. Reduce the occurrence of wood deformation, internal cracks, end cracks, and other phenomena.

The electrical energy of the wood dryer machine is mainly used for small wood drying equipment and occasions with high control standards. The electric energy is converted into heat energy through the electric heating tube, heating the drying medium. Electric energy is a high-level energy source without any pollution problems. It can be used as a heat source alone or as a secondary heating device together with other heat exchange equipment. However, when using electric heaters, please note that the outlet temperature of the hot air should not exceed 350 ° C. The electric heater burns out, and the connection part of the wire may be easily fused. In addition, if the outlet temperature of the electric heater is not below 100 ° C during a power outage, the fan cannot be turned off to prevent the machine from burning.

The hot air temperature can be adjusted and controlled in the range of 35 ° C ~ 100 ° C according to the needs of the wood, which realizes the drying of various hardwoods, hardwoods, cork, veneer, board, plywood, etc. This is achieved by the solenoid valve controlling the steam inlet volume. The temperature difference is small, the drying speed is fast, and the quality is high.

Wood generally chooses wood dryer machines according to its own needs. Wood drying methods include gas wood dryer machines, hot oil wood dryer machines, diesel wood dryer machines, and microwave wood dryer machines. The following small series introduces a simple method of drying wood, an electric heating wood dryer machine.

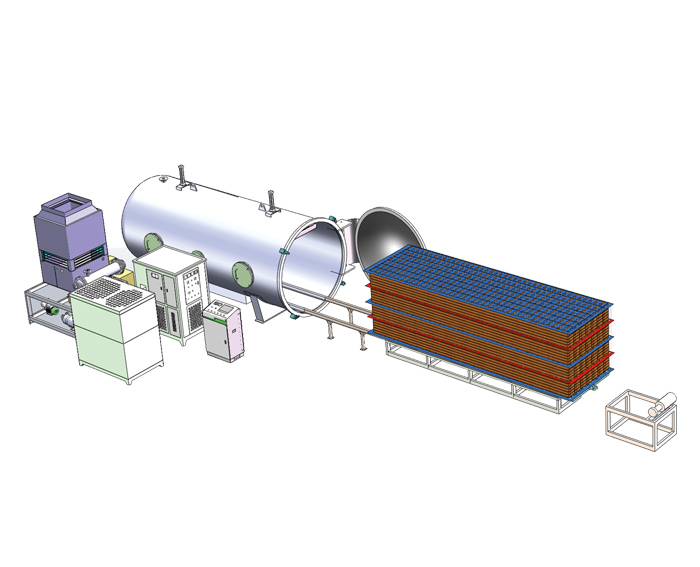

Electric wood dryer machines use electricity as the heat source, and the equipment is composed of electric heat sink fins, high temperature, and high humidity axial fans, diversion systems, circulation systems, control systems, drainage systems, etc. The operation is simple and convenient.

The above information is provided by wooden joining machine manufacturer.

Copyright © Shijiazhuang Cangao High Frequency Machinery Co., Ltd. All Rights Reserved | Sitemap |